RUTH Hydrophilic polyurethane grout

| Place of Origin: | SHANGHAI, CHINA |

| Brand Name: | RUTH |

| Model Number: | IP-11 |

| Certification: | CE/ISO |

| Minimum Order quantity | 100 KGS |

| Package Details | 10kgs/20kgs/drum or Customized |

| Delivery Time | 7 to 15 days |

| Payment Term | T/T, L/C, paypal, western union |

| Annual Production | 5000 Tons |

- Overview

- Recommended Products

Quick Detail:

1. Different names:

Water-Activated Polyurethane Injection Grout/ Hydrophilic PU Injection Grout/ Hydrophilic Grout

2. Main uses:

RUTH manufactures premium Hydrophilic Polyurethane Grout for stopping active leaks. Our water-activated resin creates a flexible foam/gel for curtain grouting, tunnel waterproofing, and sewer rehabilitation. Direct factory pricing.

3. Extreme Performance:

Water Absorption Capability is up to 30times of water

Description:

RUTH WPU IP-11 is an advanced, single-component hydrophilic polyurethane grout engineered for permanent leak sealing. Its ultra-low viscosity allows it to penetrate deep into the finest cracks and joints, where it actively seeks out water to form a tough, flexible, and impermeable gel seal. This hydro-active reaction effectively stops water by fully encapsulating it within the cured resin, creating a resilient, waterproof barrier that withstands structural movement and vibration.

RUTH Hydrophilic Polyurethane Grout is a professional-grade, single-component injection resin designed to stop active water leaks in concrete structures. Unlike hydrophobic materials that repel water, our hydrophilic polyurethane resin seeks out and absorbs water, reacting to form a flexible, closed-cell water stop foam or a high-density gel.

As a leading manufacturer, RUTH formulates this expanding polyurethane grout to provide a permanent, watertight seal that accommodates thermal expansion and structural movement. It is the preferred choice for curtain grouting injection and sealing hairline cracks where moisture is constantly present.

Primary Applications

Our Hydrophilic PU is engineered for critical infrastructure and civil engineering projects:

Water Stop Injection: Stopping active leaks in basement walls, elevator pits, and parking garages.

Curtain Grouting Injection: Creating a waterproof barrier behind foundation walls or tunnel linings (soil-structure interface).

Tunnel & Dam Waterproofing: Sealing construction joints and cracks in tunnel waterproofing grout repair projects.

Sewer & Manhole Rehabilitation: Sealing joints in wastewater infrastructure and manholes (manhole rehabilitation) to prevent infiltration/exfiltration.

Soil Stabilization: Can be used for permeation grouting in loose soil conditions.

Technical Specifications:

| ITEM | Standard Index | Test result |

| Density(g/cm3 25℃±0.5℃) | ≥1.00 | 1.08 |

| Viscidity (Mpa.S 25℃±0.5℃) | ≤1.0 ×103 | 910 |

| Gel Time / S ( add 20 times water) | ≤150 | 98 |

| Water Absorption Capability / times of water | ≥20 | 25 |

| Non-volatile Content/ % | ≥78 | 80.4 |

Key Features & Benefits

High Expansion Ratio: Reacts immediately with water to expand (typically 10x-20x), effectively filling voids and stopping high-flow leaks.

Flexible & Resilient: Cures into a tough, flexible polyurethane grout that will not crack under dynamic stress or vibration.

Excellent Bond Strength: Adheres aggressively to wet concrete, creating a lasting injection grouting waterproofing barrier.

Single-Component Efficiency: Pre-catalyzed for immediate use; simpler operation and faster cleanup.

Chemical Resistance: Resistant to sewage, mild acids, and saltwater, making it ideal for sewer rehabilitation grout applications.

Why Choose RUTH?

Factory Direct: We produce over 5,000 tons of grouting materials annually, ensuring consistent quality and competitive pricing for Specialty Distributors and Specialist Subcontractors.

Complete System: Our grout is perfectly matched with RUTH’s injection grouting machines and mechanical packers (aluminum/steel/plastic) for a seamless application experience.

Global Export: We ship bulk quantities of pu grouting material worldwide, ensuring supply chain stability for your projects.

FAQ: Hydrophilic vs. Hydrophobic?

Q: When should I use Hydrophilic Polyurethane Grout?

A: Use Hydrophilic when you need a flexible seal that creates a permanent bond with wet concrete. It is best for curtain grouting, cracks that may move, and areas that stay consistently wet. If you need rigid soil stabilization or high-pressure water cut-off in dry environments, consider our Hydrophobic Polyurethane Grout.

Product Color

|

|

|

White colloid After reaction with water |

Light Yellow

Product Color

|

Drum Details,

|

|

|

|

Packaging & Storage

· Packaging: 10kg and 20kg sealed iron pails.

· Shelf Life: 6 months in original, unopened container.

· Storage: Store indoors in a cool, dry, well-ventilated area, away from direct sunlight and heat sources.

Quality Control / Test Methods

RUTH Quality Assurance: How We Test

At RUTH, consistency is our promise. Every batch of our Hydrophilic Polyurethane Grout undergoes rigorous testing before shipment. Here is our standard lab test method for ensuring non-shrink performance:

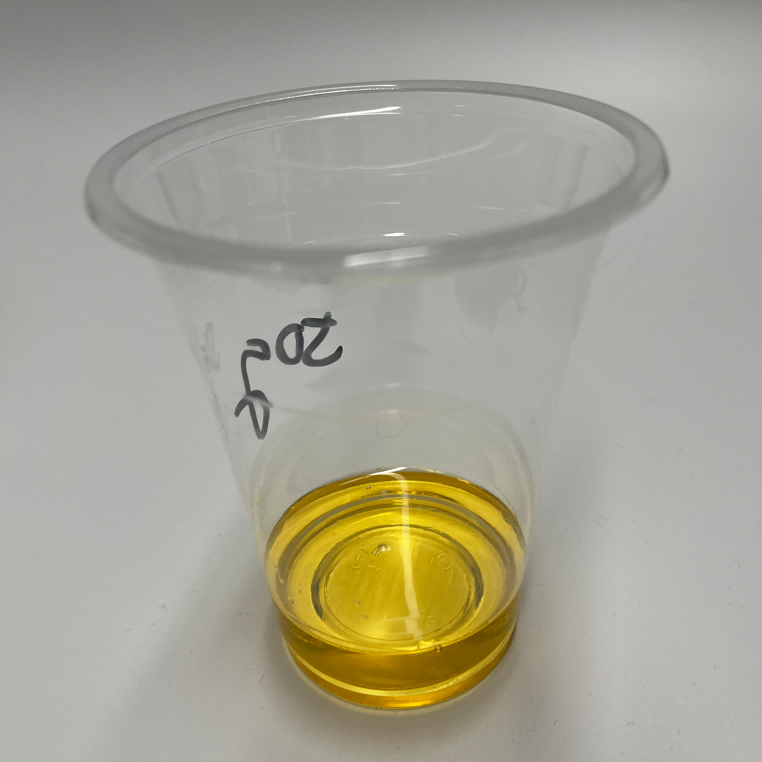

Test Method: GEL TIME Determination

Introduction

Testing the gel time is crucial for evaluating the reactivity and quality of Hydrophilic Polyurethane Grout. A consistent gel time ensures the water-activated resin will perform predictably during curtain grouting or leak sealing applications.

a. Preparation & Mixing Using a precision balance, weigh 20g (±0.1g) of Hydrophilic Polyurethane Grout into a 250ml beaker or paper cup. Separately measure 100g of water. (Note: This represents a standard 1:5 Resin-to-Water ratio, commonly used to test material stability).

b. Reaction Initiation Quickly pour the 100g of water into the beaker containing the polyurethane injection resin. Simultaneously start the stopwatch the exact moment the water is added.

c. Agitation Stir the mixture continuously and vigorously while adding the water. Ensure the mixing is uniform; this process should take approximately 10 to 15 seconds.

d. Observation & Gel Point Observe the mixture as it turns into a white milky emulsion. Continuously probe the viscosity of the liquid using a glass rod. The Gel Time is confirmed when the glass rod is lifted from the liquid and "stringing" (formation of gel threads/filaments) occurs. Stop the stopwatch immediately. This duration is the official Gel Time.

Test Conditions & Accuracy

Temperature Control: Ensure the water temperature is maintained at 23±2°C, with an optimal target of 25°C. Temperature is the primary factor affecting the reaction speed of hydrophilic grout.

Data Verification: Conduct three parallel tests and calculate the average value. This ensures the reliability of the performance data for the chemical grouting material.

Variable Ratios: This method can also be adapted to test different expansion ratios (e.g., 10x, 15x, or 20x water dilution) to simulate various job site conditions.

Gel with 10times of Water

Call to Action Section

Stop Leaks Permanently with RUTH Technology Are you a distributor or contractor looking for a reliable Hydrophilic Polyurethane Grout supplier?