RUTH High-Pressure Injection Packers (Mechanical & Surface Ports)

High-Pressure Injection Packers | Aluminum, Steel & Surface Ports Manufacturer - RUTH

URL Slug: /ruth-injection-packers

| Place of Origin: | Shanghai,China |

| Brand Name: | RUTH |

| TYPE | Aluminum |

- Overview

- Recommended Products

Quick Detail:

Different Names: Aluminum injection packers/Grouting Packer/Packer Injection

Mainly Supply:RUTH manufactures a full range of Mechanical Injection Packers (Aluminum/Steel) and Surface Ports for PU and Epoxy grouting. Bulk supply for distributors. Sizes A10, 13mm, and custom.

RUTH Injection Packers (also known as mechanical packers) are the critical connection point for successful injection grouting in concrete. We manufacture a complete range of high-performance packers designed to withstand extreme pressures during polyurethane injection and epoxy crack injection.

As a leading injection packers supplier in China, RUTH controls the entire production process—from rubber seal expansion testing to threading precision—ensuring no leakage or breakage on your job site.

Product Categories

1. Aluminum Injection Packers (The Industry Standard)

Best for: General polyurethane foam crack injection and water stopping.

Features: Cost-effective, lightweight, and suitable for mid-to-high pressure applications.

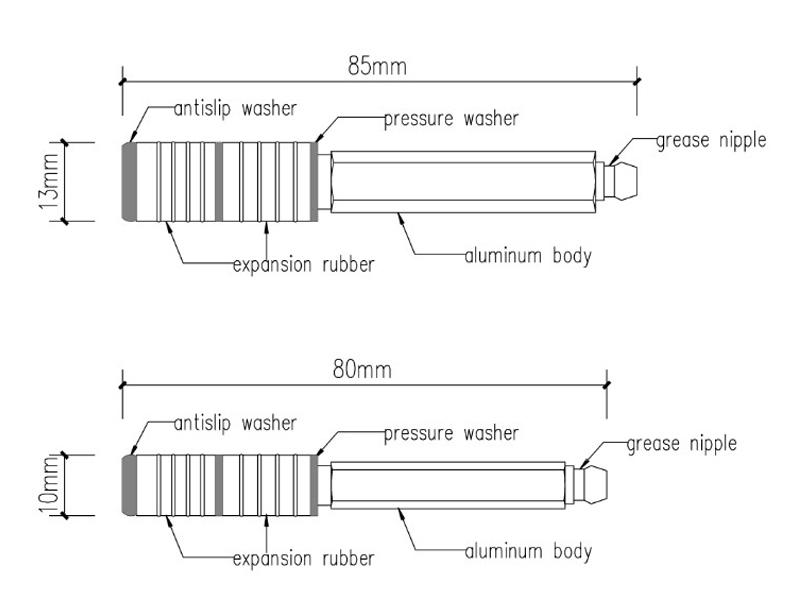

Popular Sizes: Injection Packer A10 (10mm/13mm), varied lengths from 8cm to 25cm.

2. Steel Injection Packers (Heavy Duty)

Best for: High-pressure hydrophobic polyurethane grout injection and deep structural repair.

Features: Maximum durability. Won't shear off under extreme torque or pressure. Ideal for hard concrete and deep holes.

3. Surface Injection Packers (Surface Ports)

Best for: Structural epoxy injection where drilling is not possible (e.g., preserving rebar or thin substrates).

Features: Mounted directly over the crack using epoxy adhesive (epoxy injection packers).

Why RUTH Packers? (Key Features)

Superior Rubber Expansion: Our rubber sleeves are engineered to expand evenly, creating a perfect seal inside the drill hole to prevent grout backflow (packer injection safety).

Universal Compatibility: Fitted with standard Zerk fittings (grease nipples) or Button Head fittings, compatible with any standard high pressure grease coupler.

One-Stop Supply: We supply everything from the pu injection packer to the pump and the resin.

Bulk Pricing: We offer the most competitive injection packers price for distributors ordering in cartons or pallets.

Applications

Crack Injection: Inserting crack injection packers into drilled holes to deliver PU foam into wet cracks.

Curtain Grouting: Using long packers for deep soil or structure interface injection.

Epoxy Bonding: Using surface ports for low-pressure epoxy injection for structural bonding.

Specifications:

| Technical Parameters | |||||

| Open pressure | 10MPa/1465psi/100bar | ||||

| Of nozzle | |||||

| Grouting Performance | High-pressure grouting, easy to inject, simple construction, convenient cleaning | ||||

| Application Scope | Subway, tunnel, reservoir, underground structure, hairline cracks, construction joints, expansion joints, cracks, ground improvement, port construction, ground leveling, and other renovation projects | ||||

| Regular Sizes | 10*80 | 10*100 | 13*85 | 13*100 | 13*150 |

| (mm) | |||||

| Gross Weight | 13.5 | 15.5 | 22.5 | 24.5 | 15.5 |

| (kgs) | |||||

| Packaging Specs | 1000 | 1000 | 1000 | 1000 | 500 |

| (pcs/Carton) | |||||

※ 8CM, 8.5CM, 10CM are used for dense structures, 15CM for loose structures; other lengths can be customized

Competitive Advantage:

High toughness rubber, not easy to be fragile

High-quality aluminum, not easy to be bent

Endurable in high pressure

Good waterproof effect, stable quality, convenient operation

CONSTRUCTION METHOD

01 Find Cracks

For wet base layers, first clean accumulated water; for dry base layers, clean surface dust. Carefully find cracks and mark them with a crayon or chalk.

02 Drilling

According to the concrete structure thickness, drill holes 50-150mm away from the crack on both sides along the crack direction, intersecting the crack. The drill bit diameter is 14mm. The intersection with the crack cross-section should be at an angle of 45-70 degrees, and intersect within 1/2 of the structure's thickness.

03 Bury Water-Stop Needle

Use a tool to bury and fasten the needle, ensuring the rubber part of the water-stop needle and the hole wall are dry before use, otherwise, it is easy to cause slippage when tightened.

Unmatched Durability: Automotive-Grade Grease Couplers

Stop wasting money on fragile couplers that burst under pressure. RUTH’s High-Pressure Zerk Couplers are engineered using imported metallurgy technology and premium alloy steel.

Automotive Heritage: Our couplers undergo heat treatment at the same world-class processing center used by famous automotive brands. This ensures superior hardness and toughness.

Zero Breakage: Designed to withstand extreme high-pressure cycling without fracturing.

Proven Longevity: In a real-world field test, a contractor used just 50 pcs RUTH couplers (with 2000pcs rubber ring of Coupler ) throughout an entire year. That is the definition of reliability.

Customization for Market Advantage:

Stand Out with RUTH's "Wide-Neck" Design

In a market filled with standard packers, product differentiation is key to building your brand. We offer an exclusive Wide-Neck Design option that solves a common pain point for contractors: difficulty in gripping the grease nipple.

The Problem: Standard packers have narrow necks, making it hard to use a wrench to tighten or loosen the Zerk fitting.

The Solution: Our widened hexagonal neck allows for easier wrench access and higher torque application.

The Result: A superior user experience that keeps your customers loyal to your brand.

Call to Action

Stock Up on Premium Packers

Looking for reliable Injection Packers Suppliers? Get a quote for a pallet of Aluminum A10 or Steel packers today.