📦 Packaging & Storage

Packaging: Available in 10KG and 20KG pails.

Storage Conditions: Store in a cool, dry, indoor location in the original sealed container. Keep away from direct sunlight, rain, and heavy weight.

Shelf Life: 6 months (when stored under recommended conditions).

Engineered for Geotech: We understand the needs of foundation repair contractors. Our foam provides the lift and stability required for slab jacking projects.

Supply Chain Security: As a manufacturer with 5,000 tons annual capacity, we offer bulk pu foam grouting material at competitive factory-direct prices.

Complete Injection Solutions: RUTH supplies the full ecosystem, including grout injection kits, high-pressure pumps, and durable steel injection packers capable of withstanding the pressures required for hydrophobic injection.

FAQ: Why Use Hydrophobic Grout?

Q: Why choose Hydrophobic IP-12 over Hydrophilic grouts?

A: Hydrophobic polyurethane repels water and cures into a rigid foam that does not shrink when the surrounding area dries out. This makes IP-12 the only correct choice for soil injection grouting, concrete lifting, and stopping leaks where the water level fluctuates (wet/dry cycles). Hydrophilic grouts may shrink and lose their seal if they dry out.

Quality Control / Test Methods

RUTH Quality Assurance: How We Test At RUTH, consistency is our promise. Every batch of our Hydrophobic Polyurethane Grout undergoes rigorous testing before shipment.

Here is our standard lab protocol for ensuring non-shrink performance

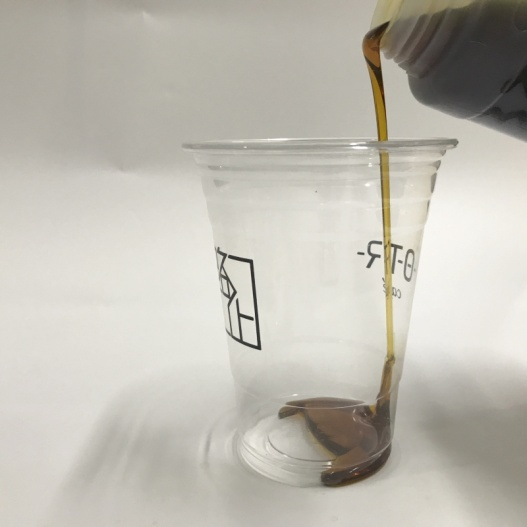

Test Method: Curing & Rise Time Determination

Testing the curing and rise time is essential to determine how Hydrophobic Polyurethane Grout (Oil-based PU) will behave in real-world applications like high-pressure leak sealing or soil stabilization. This test confirms the reaction speed and the foam's structural stability.

1. Sample Preparation

Using a precision balance, weigh 20g (±0.1g) of Hydrophobic Polyurethane Grout (often referred to as Oil-based PU) into a 250ml beaker or disposable paper cup.

2. Catalyst/Water Addition

Add a minimum of 1.0g of water to the cup (approximately 5% of the resin's weight). (Note: Since this is a hydrophobic material, water acts as the blowing agent to initiate the expansion reaction).

3. Agitation & Mixing

Immediately upon adding water, stir the mixture rapidly and vigorously.

Mixing Duration: Continue stirring for approximately 15 to 25 seconds.

Visual Cue: The mixture is considered uniform when the oil-based resin and water combine to form a pale yellow, frothy emulsion state.

4. Recording Reaction Time

Start: Start the stopwatch the exact moment the water is introduced to the resin.

End: Observe the rising foam. Stop the stopwatch when the hydrophobic foam completely stops rising (reaches maximum volume).

Result: This duration is recorded as the Full Rise Time (often used to indicate the complete curing time for field applications).

5. Stability Observation

Allow the cured foam sample to sit at room temperature for 10 hours.

Check for Shrinkage: Inspect the foam structure. High-quality Hydrophobic Polyurethane Grout should remain rigid and show no signs of shrinkage. This "non-shrink" property is critical for applications like polyurethane foam injection concrete lifting and filling voids, ensuring long-term structural support.

Secure Your Project Foundations with RUTH IP-12 Need a quote for bulk Hydrophobic Polyurethane Grout or finding a supplier for your concrete lifting business?