The Engineering Challenge: Severe Cold & Structural Vibration

The Shenyang Municipal Overpass is located in a region known for its harsh winters and significant temperature fluctuations. The project team faced severe challenges that traditional materials simply could not withstand:

1. Expansion Joint Failure: The bridge’s deformation joints and expansion joints were leaking due to material fatigue. Traditional polyurethane sealants lacked the necessary elongation to handle the bridge's significant thermal expansion and contraction cycles, leading to secondary cracking.

2. Operational Nightmares: Previous maintenance methods required the tedious and time-consuming cleaning of V-shaped steel joints. This process often required extended lane closures, causing significant traffic disruption.

3. Dynamic Load Failure: Constant traffic vibration caused rigid fillers (like standard epoxy crack filler) to de-bond from the concrete base, rendering the seal useless.

The contractors needed a flexible polyurea grout that could be applied quickly, cure in cold conditions, and withstand long-term structural movement without failure.

The Solution: A Breakthrough in Single-Component Polyurea Technology

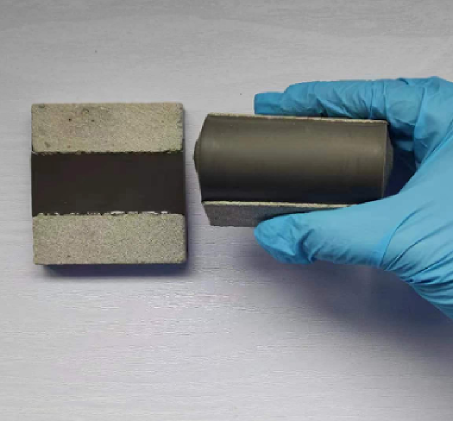

RUTH introduced its proprietary Single-Component Polyurea Grouting Material (IP-Series). This material represents a generational leap in bridge maintenance technology. Based on a polyurea prepolymer core combined with mineral fillers, it forms a homogeneous liquid system that solidifies into a dense, rubber-like structure upon contact with water or moisture.

1. Eliminating the "V-Shape" Headache

One of the most praised aspects of the RUTH solution was the simplification of the construction process. Customer feedback specifically highlighted that this material eliminated the need for the tedious cleaning of V-shaped steel joints. Unlike traditional methods that require perfectly clean and dry surfaces, RUTH’s polyurea joint filler is compatible with manual scraping techniques. This allowed the construction team to achieve rapid sealing without complex surface preparation, greatly reducing labor costs and minimizing the impact on municipal traffic.

2. Superior Performance Metrics

Water-Curing Chemistry: The material utilizes a unique water-curing mechanism. It creates a dense bond even on damp concrete bases, forming a continuous waterproof barrier that resists water vapor penetration.

High Elasticity & Deformation Adaptability: With high strength and high elongation, the cured elastomer effectively absorbs the expansion displacement caused by temperature drops and load vibrations. It avoids the "secondary cracking" common with rigid grouts.

24-Hour Watertightness: Post-application testing confirmed that the repaired joints passed a 24-hour watertightness test with zero leakage, validating its reliability for critical infrastructure.

Environmental Responsibility: The "Green Construction" Standard

In alignment with global trends towards sustainable engineering, RUTH’s polyurea solution sets a new benchmark for environmental safety.

Solvent-Free Formulation: The material boasts a high solid content and contains no harmful solvents like benzene. This poses no pollution risk to the surrounding environment or the health of the construction workers.

Safety in Application: Being a cold-applied liquid, it eliminates the fire hazards associated with hot-applied bitumen or torch-on membranes. It allows for safe, flexible construction even in challenging site conditions.

Hot News

Hot News